Q1. How has IT changed the definition of “logistics”?

The way that IT changed the

definition of “logistics”

Bowersox 1969: “Business

logistics” is defined as the physical distribution of goods from the place of

production to the consumer and the movement of raw materials to the place of

production. It concerns with inbound supplies and outbound products.

1960s to 1970s: The logistics

management is divided function by function, such as demand forecasting,

purchasing, requirement planning, production planning, etc.

1980: there is evolving

integration, which is to focus both inbound and outbound logistics within

companies and the movement of finished goods from dock-to-dock.

Transportation industry becomes

not only about the physical transportation, but also the coordination and

control of storage and movements of parts and finished goods.

The value-added activities are

also provided, which include order processing, distribution center operations,

inventory control, purchasing, production and customer and sales services.

The IT system including

internet, intranets and integration of systems let companies redefine

themselves and re-engineer their selling and supply chains.

Just-in-time inventory

management reduces costs and improves efficiency.

With the invention of IT,

logistics companies not only handle the physical delivery, but also manage and

utilize the flow of information to control over the movement of goods.

Ballou 1992: Redefine logistics

to incorporate three key activities, namely: transportation, inventory

management and order processing.

It shifted from inward-looking

view concerned with efficiency and cost-reduction to an outward focus on

improving customer services.

Mabert 1998: Redefine logistics

as “the process of planning, implementing, and controlling the efficient,

cost-effective flow and story of raw materials, in-process inventory, finished

goods and related information from point of consumption for the purpose of

conforming to customer requirement.

The charge is the direct result

of increasing use of information and communication technologies.

Q2. List the benefits of a virtual supply chain.

The Benefit of Virtual

Supply Chain

Virtual supply chains are

designed for flexibility, complexity and speed in managing networks of

suppliers, manufacturers, distributors and warehousing agents virtually. FedEx

has experienced process of re-organization and re-engineering in the past, it

has developed a series of information technology systems to help cope with the

logistic process. For instance, systems like COSMOS and EDI are highly

integrated. The discussion will be followed by some specific benefits driven by

each of the information technologies FedEx has adopted. In general,

Internet-enabled system allows implementation of checking of inventory levels,

order status as well as product delivery schedules. It can also decrease the

time to market for a product. Just-in-time inventory management contributes to

the freight to be ready within the shortest time as possible. Responsiveness is

effectively improvement.

Greater transparency and

convenience in information sharing

Continuous updated information in COSMOS improves

communication along the logistics value chain – including various departments

in FedEx and customer. For instance, information was inputted constantly by

various mean into COSMOS so that data can be relayed on package movement,

pick-up, invoicing and delivery to central data base. When COSMOS is updated,

customer can find out at any time exactly where their package is and when they

can expect delivery through call, web site or FedEx’s software. It also helps

promote the globalization of markets. Since systems enable manufacturer to

extend global reach for sourcing of parts or component as and required. By

locating production plant in geographic locations can minimize costs without

compromising on speed to market too.

Provide one-stop solution

for its customers, buyers and suppliers

One to one relationship can be built. For its

business partner, EDI (Electronic Data interchange) and internet enable

manufacturer to match supply to demand without wastage. EDI can help Improve

inventory level and squeezing time out of the system by redefining sources and

procurement strategies so as to reduce cost and increase profitability.

Importantly, management service including transportation, order processing and

distribution center operation can also be improved by identifying potential to

provide such service in the chain. For customers, since such practice can

improve efficiency from point of ordering to point of delivery, FedEx has

improved its ability to satisfy customers through speedy and accurate

fulfillment.

Better value-added

service and improvement in efficiency

Just-in-time inventory management can help reduce

cost including warehousing cost and wastage through obsolete stock. It provides

high flexibility in relation to changing marketing conditions in terms of the

volume of production and in terms of production modification. Some additional

service provided by FedEx like Power Ship System is an example. It provided for

high-volume shipper with high speed, secure connectivity to streamline

customer’s supply and relevant data into their existing system. Customer can be

more loyal to the company and decrease switching cost. Loyal customer leads to

stronger brand positioning that rise the barrier of entry. Marketing and

administrative cost can then be saved.

Q3. Discuss the role of IT in FedEx’s Business Strategy.

The Role of IT in FedEx’s

Business Strategy

IT changes the way company connects with each other

in the new network economy. According to the founder, Frederick W. Smith, he

considered that the information about a package is as important as the delivery

of the package itself. FedEx’s core corporate strategy was to use “IT to help

customer take advantages of international market”. The huge expenditure on IT

development has boosted the following two,

Innovate the business it

operates and increase business opportunity

1)

Generate

process efficiencies

2)

Help

re-define and re-engineer logistic and supply chain

3)

Maintain

positive control over shipments every step of the way

4)

FedEx

considers IT not additional to core business, but it is the core business

Innovate the “customer”

it interacts and build closer relationship

According to the research done by Forrester

Research, it indicated that 42% of

online buyers are willing to spend between 6-10% of product value for shipping.

1)

Customer may

have a single point of access to the Group

2)

Advanced in

customer ordering, package tracking and process monitoring

3)

Build

one-to-one relationship with customer due to system synchronization

4)

Provide an

tailor-made and integrated platform for storing, retrieving and updating data

5)

Existing

technologies help track back along the supply-chain to the point of raw

materials

6)

IT also help

business customer like Cisco solve operational problem such as selecting routes

and pick up the most effective and economical mode of transportation

Innovate the market it

involves as a whole

1.

Satisfying

changing market demand

2.

Technology

attracts potential partners to cooperate in running business

3.

Defend its

business and differentiate from competitors

4.

Increase

barrier of entry due to the adoption of technologies in advance

Q4. Discuss the virtual integration of supply chains without ownership.

The Virtual Integration

of Supply Chain without Ownership

The traditional model promoted vertical integration

as the best way to ensure control of the production process and to maintain

competitive edge. As technology advanced, vertical integration is gradually

replacing vertical integration. Technologies have improved efficiency along the

supply chain without ownership of the links of the chains. To maintain such

competitive advantage, that will result in increasing customer’s switching

costs and build stronger brand loyalty. Parts of customer’s operational

activities, which may not be their specialized functions, are outsourced to

FedEx to support the business operation so as to increase efficiency.

FedEx had set a few records with breakthrough

technologies, these technologies bring a greater convenience and efficiency

along with effective integration. The connection among various stages in the

chain is heavily linked to virtual platform. Followings are the techniques

applied to different parties for FedEx and help smooth the flow of information,

product and cash within supply chain.

Hand-held scanner (For

Courier)

Hand-held scanners were issued to its drivers that

alerted customer of when packages were picked up or delivered. This was made

possible by placing a bar-code on each parcel at the point of pick up and

scanning the bar-code at each stage of the delivery cycle. Hand-held scanner is

also called Super Trackers which are used to scan the progress of the package

an average of 5 times from pick-up to delivery.

Super Trackers retain and transmit package

information such as destination, routing instructions and the type of service

requested. Once a courier returns to the van, the information is downloaded

from the Super Tracker to DADS, which updates the package location in the

COSMOS system. DADS is a small digitally assisted dispatch computer

systems found in courier vans that help transfer information to COSMOS.

COSMOS (For Company

Database)

It is called “Customer, Operation, Service, Master

Online System”. It primarily kept track of all packages by the Company. The

system monitored every phase of the delivery cycle at Federal Express. Data

retrieval is done by downloading the information from courier’s Super Tracker

(Scanner) when pick up or deliver the goods. FedEx’s customer service

representative and customer may access them by the designated means.

FedEx software (For

Customer)

It gave away 100,000 sets of PCs loaded with FedEx

Software which designed to link and log customers into FedEx’s ordering and

Tracking System. The software is called “FedEx Ship Manager Software”

which can be downloaded from official website.

Functions enable customer to track the status

of their packages and notify them of package arrivals, monitor shipping usage

with easy-to-read reports and integrate shipping into customer’s company’s

ordering and fulfillment database. Information provided by this software is

highly integrated with other technological systems within its company. These

information technologies are highly integrated to perform the smooth sequence

of data convey. When any of these technologies break down, the rest of them

will be affected. Therefore, maintaining a healthy operation of the above

technologies normally cost the company a huge amount of money. FedEx has

differentiated itself from traditional practice, it is definitely famous for

its technologies and outrun other companies in same industry.

Other additional service

integration

Power Ship Program provides additional service to

customer including storing of frequently used addresses, label printing, online

package pick-up requests, package tracking. It aimed to improve efficiency and

control.

Besides, virtual integration of supply chain was

not only demanded by FedEx, but also by its innovative customers. A company,

Cisco, has developed an extranet that allowed its customers to order FedEx

service without leaving the Cisco Website. The interactive integration online

between FedEx’s customer and partner helps FedEx to raise barrier to entry for

competitors.

Q5. What are the factors that put pressure on FedEx to

consolidate its operations, while remaining customer-focused?

The factors that put pressure

on FedEx to consolidate its operations, while remaining customer-focused

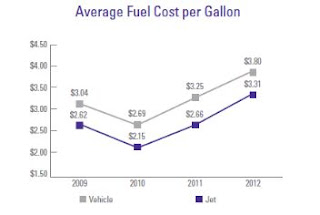

Rising Price

First of all, rising fuel price

had severely impacted upon the Company’s net income. Cost of fuel charges large

proportion of the variable cost of transportation. It affects the operating

income a lot. According to the Annual report of FedEx, the average fuel cost

per gallon kept rising from 2010 to 2012. Fuel expense increased 19% during

2012 primarily due to price increases. The amount of the surcharge is closely

linked to the market prices or fuel. If FedEx is unable to maintain or increase

their fuel surcharges because of competitive pricing pressure, fuel costs could

adversely affect their operating result.

The Internet Market

The low cost and high diversity

of internet made it appealing and accessible to many companies. A threat

towards FedEx is that once a company was online and it fulfilled its orders to

the expectations of its customers, the size of the company was not significant.

Internet opened up opportunities in logistics management in logistics

management for FedEx as they were using the Internet to re-engineer their

supply-chains. As long as customers were

satisfied, it really did not matter whether the goods were warehoused or not,

whether the goods came directly from a factory in some distant location or

whether the goods had been made to order. So FedEx may lose its competitive

advantages.

E-tailing

E-tailing means

the selling of retail goods or services via internet. E-tailing is done mostly

with business-to-customer (B-C) transactions. Growth in e-tailing needed assistance of express

transportation to fulfill the customer expectations.

Although FedEx had put a lot resources on e-tailing, e.g. set up Caliber System, signed up with CISCO with mission of critical one stop online source for

sales tools and client information, their competitors are also doing the same

thing, utilizing internet to re-engineer the supply chain.

Intensive competition

In the logistic industry, there are loads of companies, which are both

local and global, that provided myriad of transportation services to a wide

range of businesses. Competition is vigorous. Majority of companies have already

noticed the importance of IT and invest a lot on technology. Even though FedEx

were investing millions on IT, it became the industry norm rather than a

competitive advantage. DHL, TNT and UPS, the other three leading companies in the international courier business also invest large

amount of capital to the information technology, which are aimed at

reengineering the supply chain.

Meeting customers’ demands

By

presenting the range of services under the FedEx brand and providing one

contact address, one website and telephone number for sales and customer

services, FedEx customers benefit from the more user-friendly customer

interface.

Shifting focus from customer satisfaction on product quality to service

quality

By providing

one-stop solution having the up-to-date information about customers (who they

are, what services they have been using, package delivery status etc.) helps to

promote better customer service.

Minimizing duplication of work

FedEx’s

information systems infrastructure promoted the sharing of information across

the business units to minimize the duplication of work and to better serve

customers, e.g. sharing of customer lists, logistics solutions.